CLIENT/INDUSTRY BACKGROUND

The client is the industry leader, providing top-quality closure panel solutions to the automotive industry. To provide a complete turn-key solution, they offer a fully integrated production system that supports our customers from product

design, tool development, through mass production. A VIN is composed of 17 characters (digits and capital letters) that act as a unique identifier for the vehicle

PROBLEMS

- Keeping track of each VIN manually is causing errors in recording it(VIN mismatch)

- Inventory mismanagement due to errors in recorded data

PROBLEM IMPLICATION

- Each body has unique identification numbers. Errors in recording these numbers may result in huge inventory mismanagement

- Customers would not buy a car with a VIN mismatch

CURRENT PROCESS

The inspection is being carried out by operators manually.

- A VIN consists of 17 characters that make the inspection time consuming and error-prone

- The repetitiveness of the process causes labor fatigue that increases the error rate

CLIENT REQUIREMENTS

To automate the process of OCR of Vehicle Identification Numbers (VINs) with the help of machine vision to achieve higher accuracies.

BUSINESS IMPACT

1. Increase in cost of quality (COQ)

2. Increased cost for additional labor and training

SOLUTION USING MACHINE VISION

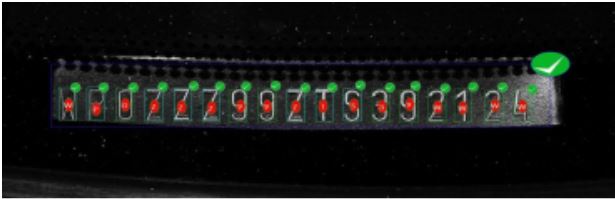

A camera or set of cameras with appropriate illumination is set up to identify the characters on the car’s body. Images are captured and sent to the software (Qualitas EagleEye® Platform) cloud where the training is done using DL algorithms. Once the program is trained, real-time OCR takes place, based on which the results are sent to PLC to take action.

IMAGES

QEP(QUALITAS EAGLE-EYE® PLATFORM)ANNOTATED IMAGES

CONCLUSION

POC(Proof Of Concept) is conducted and the following conclusion is observed:

1. OCR accuracy is closed to 100%

2. The observed labor costing is reduced