Automated Visual

Surface Defect Identification

Defect Identification Enabled By Artificial Intelligence

Identify surface anomalies like dents, scratches, paint defects on manufactured parts. A human-like teaching approach with high accuracy and precision.

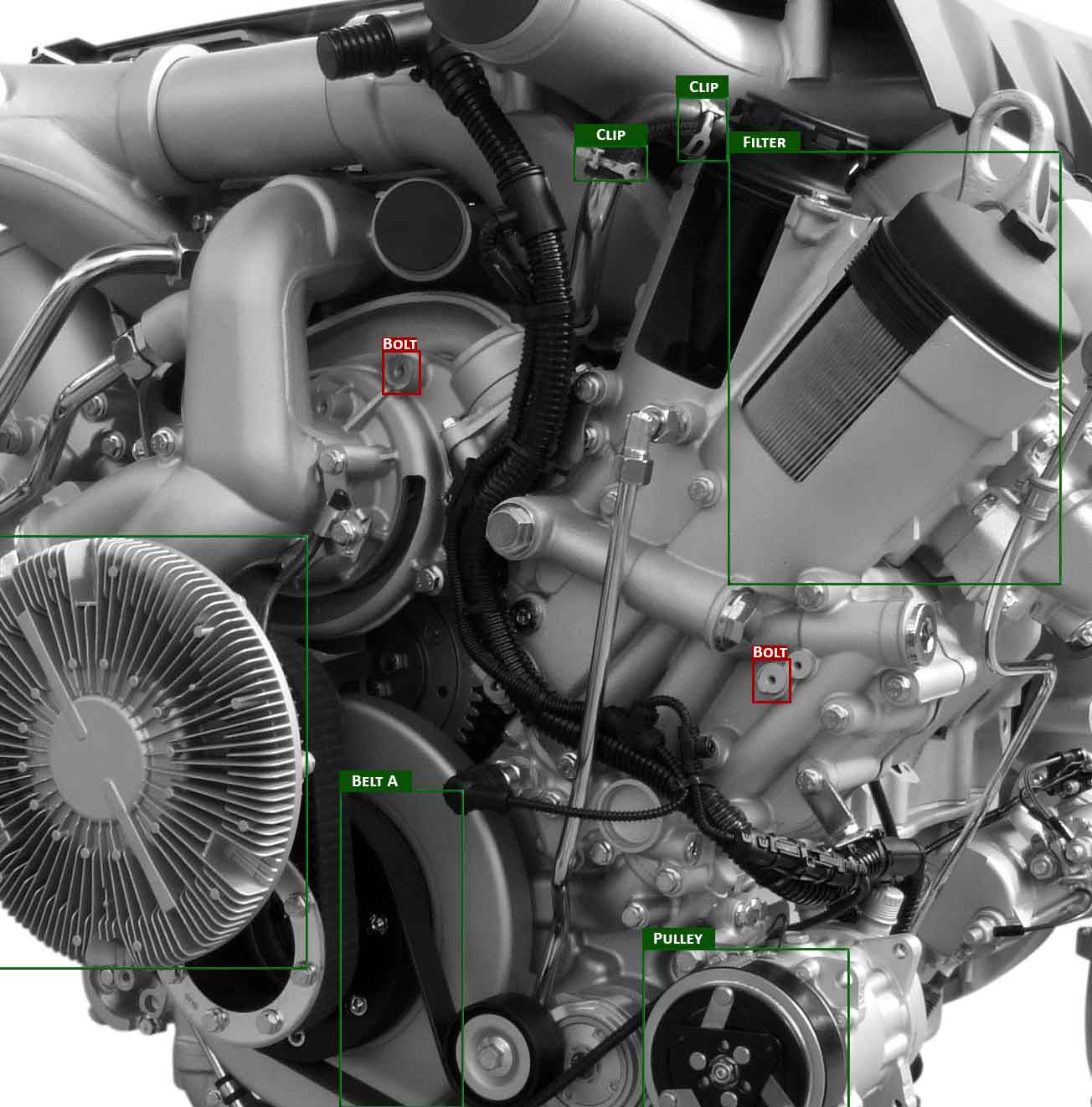

Automated Assembly Verification

Mitigate Industrial Quality Control Problems Through Verification

Visual Process Automation

Automate Processes like Counting, Character Reading, Inventory Tracking which are primarily done manually in Production Lines. Automate these processes with the EagleEye to achieve high speeds, traceability and precision.

Robotic Guidance

Enhance Robotic Pick And Place Operations With Precision Guidance

We Guide World Renowned Industrial Robots

At Qualitas, we can interface with a number of industrial robots like Kuka, Fanuc, ABB, Yaskawa, etc. to communicate the coordinates of a found location to the robotic controller.

Key Features:

- Flexible camera configurations depending on required resolutions

- Customizable imaging hardware to suit the application needs