A Complete Solution For Industrial Machine Vision Inspection Powered By Deep Learning

Qualitas EagleEye® Workflow

The Qualitas EagleEye® Suite

A complete package for machine vision solutions

Qualitas EagleEye® Hardware For Image Acquisition

Qualitas EagleEye® Edge for AI-based processing

Qualitas EagleEye® Cloud App

Qualitas EagleEye® Hardware For Image Acquisition

Image Acquisition Module that comes with different lighting, camera, and lens configuration along with a flexible mounting arm

Qualitas EagleEye® Edge for AI-based processing

Qualitas EagleEye® Edge – A highly powered Deep Learning based inferencing software. Images are captured and are inferenced with an Artificial Intelligence accelerated vision controller to run our cutting edge Deep Learning Inferencing algorithm

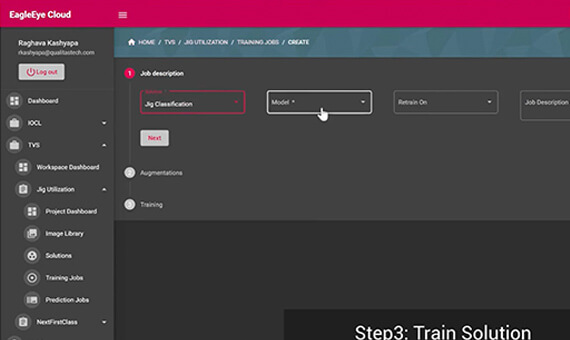

Qualitas EagleEye® Cloud App

Web Application for Image Capture, Annotation, Deep Learning Training, Deployment Management and Accuracy Measurement

4 Steps Of Qualitas EagleEye® Workflow

Quality Control Optimized With Trained AI Models

Explore what can Qualitas

EagleEye® do for You?

Ensuring Quality Assurance With Qualitas EagleEye®

Qualitas EagleEye® For Manufacturers

- Enhanced, Accurate and Consistent Quality Control Automation

- Modular Image Acquisition with multiple choices of resolutions, lighting and optics

- Complete traceability of quality inspection steps with images

- Business analytics and statistics of quality parameters

- A web dashboard to monitor System performance and Accuracy – providing 100% visibility into system performance

Customer Success Stories

Unique Features Offered By EagleEye®

Quality Control Made Simple For Manufacturing Solutions

Modular Image Acquisition

Easy To Label And Teach Software Interface

One-Step Deployment And Customizable Edge Inferencing Interface

Continuous Performance And Accuracy Monitoring

Qualitas EagleEye® For Machine Builders and Integrators

Leverage The Advantages With Qualitas EagleEye®

- Customized solutions specific to your requirements. Cost optimal, yet highly specialized, giving you an edge over the competition.

- Deployment management – keep track of all your installations and their performance right from one place.

- Deployment management – keep track of all your installations and their performance right from one place

Challenges

Machine Builders and System Integrators need to minimize costs and provide maximum value to their customers but face certain challenges:

Machine Builders have to deal with installation delays due to the complexity involved in the installation and commissioning process of machine vision solutions.

System Integrators source products from multiple vendors and face difficulty with the maintenance and solution corrections due to insufficient technical support from vendors.

Resolution With EagleEye®

Improving Efficiency With A Point & Click Interface

Qualitas Helps Machine Builders To…

- Optimize costs by minimizing delay in installations with multiple choices of inferencing hardware for specific needs

- Enhance offerings with low pricing and reduced complexity

- Enhance offerings/capabilities with value addition to machines for an aesthetic feel besides functional efficiency

Value For Machine Builders and Integrators

Differentiating Benefits

- Cost optimized Image Acquisition and inferencing Hardware designed for LEAN Integration needs

- Training on the cloud – no need for expensive GPU hardware investments and maintenance

- Deployment management – keep track of all your installations and their performance right from one place

- Accuracy Verification – Never struggle with high false positive errors. Fix them fast and quick with our fine-tuning workflow