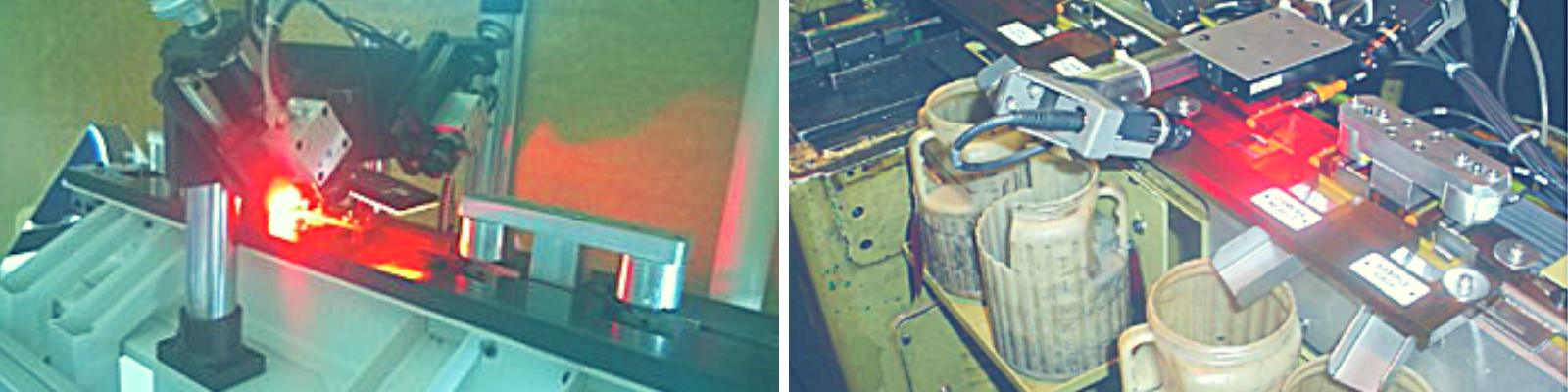

Qualitas has developed an automated taper roller inspection machine, which inspects rollers at a high speed. Tapered roller bearings have tapered inner and outer ring raceways which are designed to accommodate combined (axial and radial) loads.

The manufacturing process involves various stages and thus it’s important to inspect the rollers for defects that can occur at every stage. Due to high volumes, manual inspection becomes a challenge, and the need for automation arises.

Machine Features (For Taper Roller Inspection):

- Inspection Speed: 200 ppm (parts per min)

- Defect Area: End-face and Body

- Conveyor speed: 50 m/min

- Outer Roller Dia: 5-50 mm

- Length of Roller: 12 – 50 mm

- Software: Deep Learning (Artificial Intelligence Software)

- Multi-Language Support: EN, IT, DE, FR, Kr, Jp, CH

Here are some sample defects

- End Face Defects

- Crack

- Rusting

- Under Grinding

- Excessive grinding

- Large Inner hole

- Chamfer Defect

- Crack on chamfer

- Edge damage

Read Detailed Version – Vision-Based Surface Inspection System for Bearing Rollers Using Convolutional Neural Networks

Roller Body Defects

- Outer diameter crack

- Outer diameter scratch

- Knocked wound

- Side grinding wound

- Spiral Marks

- Rust

Get In Touch With Us