- Manual inspection of product quality can be inaccurate. This results in defective products, lack of compliance, and loss of revenue.

- Machine vision based product inspection methods can be deployed to improve product quality. Qualitas Technologies develops advanced machine vision solutions for defect detection.

- Our defect detection solution involves image preprocessing, training deep learning classifiers, and testing.

- Machine vision technology is applicable in quality control processes in different industries such as textiles, beverages, automotive industry, etc.

- Qualitas Technologies offers machine vision solutions that use a combination of modern technologies such as AI, 3D technology, and deep learning. They can be deployed to automate your quality processes that will empower you to achieve your quality goals.

Problem Statement

Starbucks recalled about 263,000 coffee presses after receiving reports of the product breaking and causing injuries. There are approximately one hundred defects that can develop in a glass container during the production process. Companies across industries are looking for solutions to reduce defects.

How can companies reduce manufacturing defects and improve product quality?

Companies have to re-imagine quality. They have to use modern technology in their manufacturing strategy to improve defect detection and enhance product quality.

If defect detection activities are not transformed, companies will not achieve their revenue targets. There will be a loss of customer satisfaction and negative public perception. Additionally, bad quality increases the operating costs of a company.

Machine Vision Using AI and 3D Technology

Artificial Intelligence is bringing in a paradigm shift in the manufacturing industry with its ability to perform tasks that typically require human intelligence. Machine vision technology is a combination of hardware and software that executes functions related to the capture of images and the processing of images. Qualitas Technologies combines AI with 3D technology to develop high-end machine vision technology that is speedy, accurate, and repeatable. Machine vision technology has wide-ranging applications in the manufacturing industry for measurement, quality assurance, guidance, defect detention, testing, and validation.

Quality control is a critical aspect of production. It involves the prevention and the detection of defects and fixing them to ensure the highest quality of output. Defect detention activities require measuring, examining, and testing characteristics of a product against specified requirements to determine conformity. Defect detention has to be consistent, accurate, and thorough. This is not always possible via manual testing. But machine vision technology can provide detailed defect detection services.

Defect Detection Method With Machine Vision

Let us examine the comprehensive process of defect detection using machine vision technology developed by Qualitas Technologies. The quality control process involves the following:

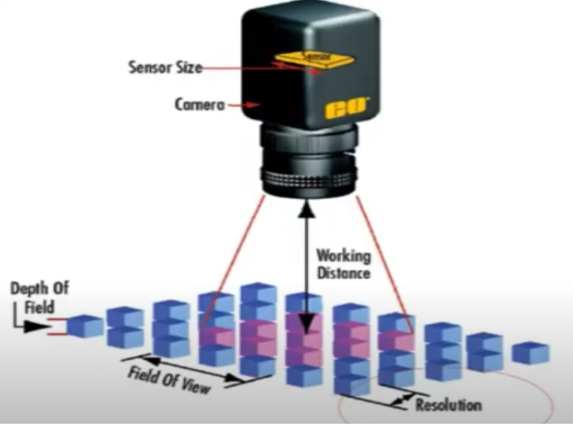

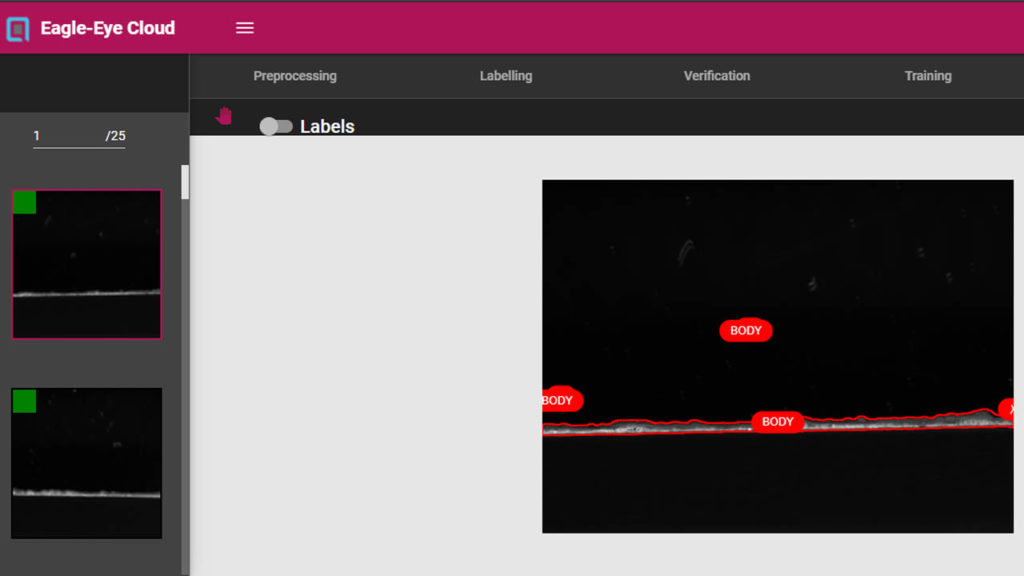

Image preprocessing

Machine vision systems have components like digital sensors and industrial cameras with specialized optics to acquire images. In this step, product information such as smoothness, surface quality, etc. is captured. If the product is a bottle or an automotive part, the cosmetic and dimension related characteristics are captured. For a pharmaceutical product like a package of tablets, the data captured will include label information, seal validation, and data code. Wrongly printed information or improperly packaged medicines can have far-reaching consequences for the pharmaceutical company.

The data is enhanced based on deep learning model requirements with video frames, images, and other data points. The product information is translated into a digital output and stored.

Training procedures

The deep learning classifier is built and trained with good samples and bad samples. The model is trained with datasets of acceptable parameters, anomalies, and acceptable anomalies to make it capable of testing with a human approach. Training is done using multiple ways such as image classification, object detection, and image segmentation

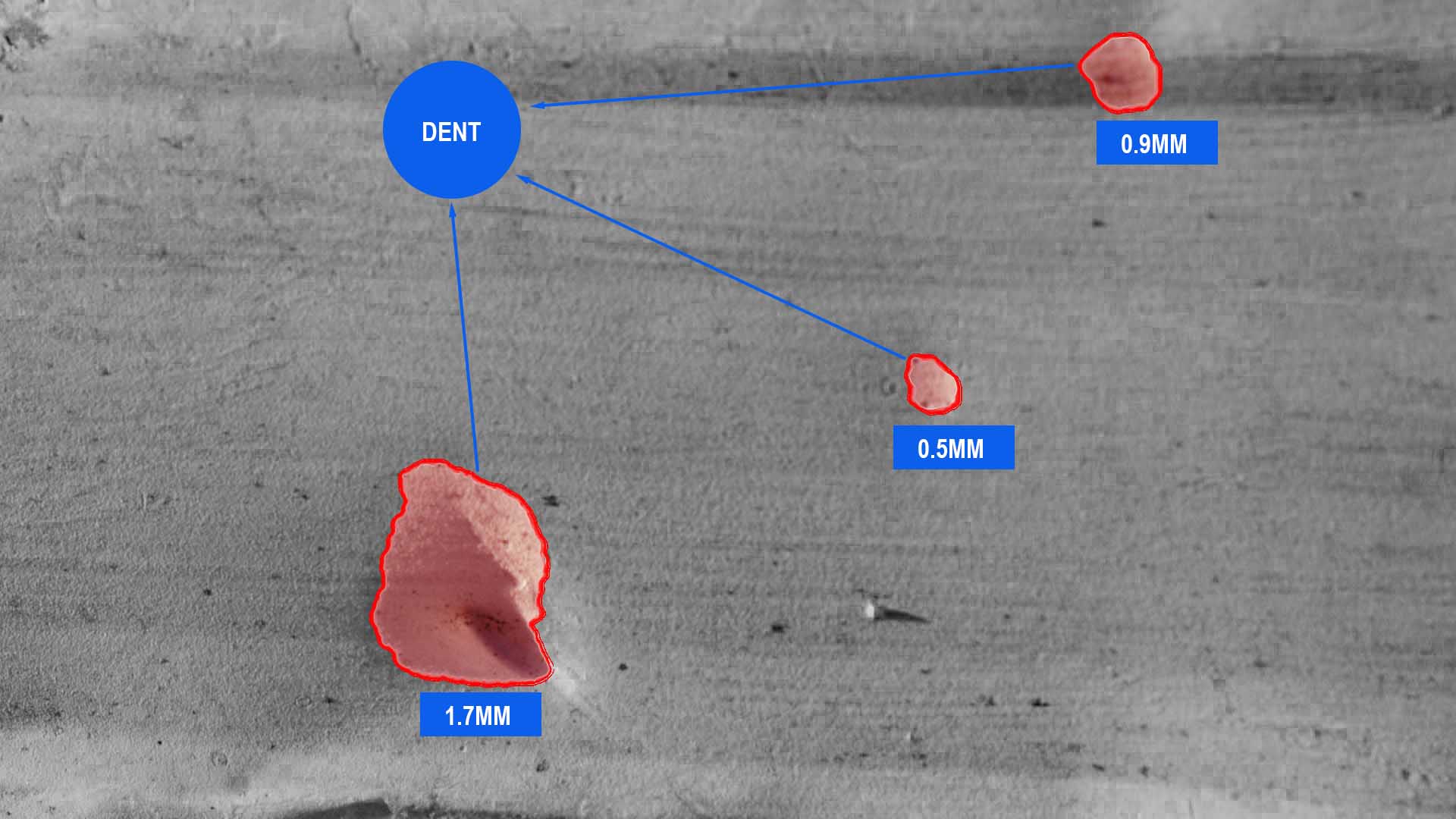

Image Classification – The algorithm assigns values for a feature set for each image based on existing data. For example, if it is an automotive part, scores can be assigned for scratches, dents, and uniformity of color.

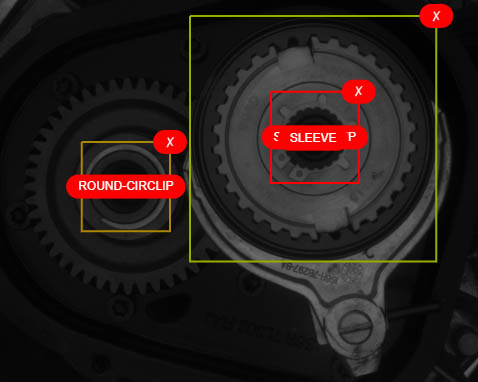

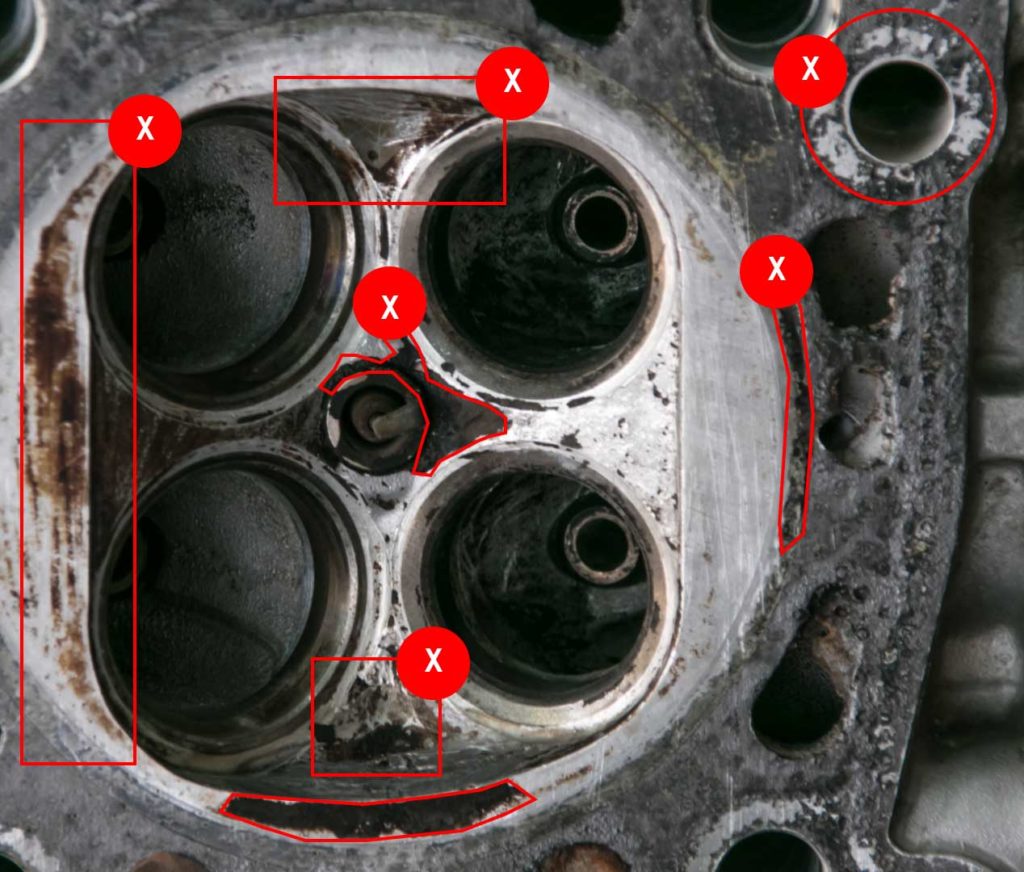

Object detection – It determines the location of errors and the number of errors in the object under test. In a bottle, it will determine the area where the scratches are and the number of scratches.

Instance Segmentation – The instances of each object such as dirt or dent are classified at the pixel level.

The more the data points and the higher the quality of data, the better the model is. The model has to be trained and evaluated for accuracy using test data. As the model gathers newer data, it gets re-trained resulting in a smarter defect detection tool.

Testing – Qualitas Technologies deploys the model for testing employing a combination of the following:

- Software – Deep learning classifiers or models that have been developed.

- Hardware – Machine vision systems have components such as digital sensors and industrial cameras with specialized optics to acquire images so that computer hardware and software can process, analyze, and measure various characteristics for decision making.

- Expected output – Test results

The product is tested and defects detected will be logged.

Application of Machine Vision Defect Detection

Businesses use machine vision in defect detection to improve the quality of end products.

Automotive Industry

Surface finish quality is a key quality parameter for automotive parts. Manual inspection of this quality does not lead to consistent results. Machine vision testing tools can inspect for paint inconsistencies, dents, and scratches consistently and accurately.

Beverage Industry

Bottles with beverages can pass through inspection sensors that have access to data on what the acceptable fill-levels are. The system can detect improperly filled bottles and log information or highlight the defective bottles.

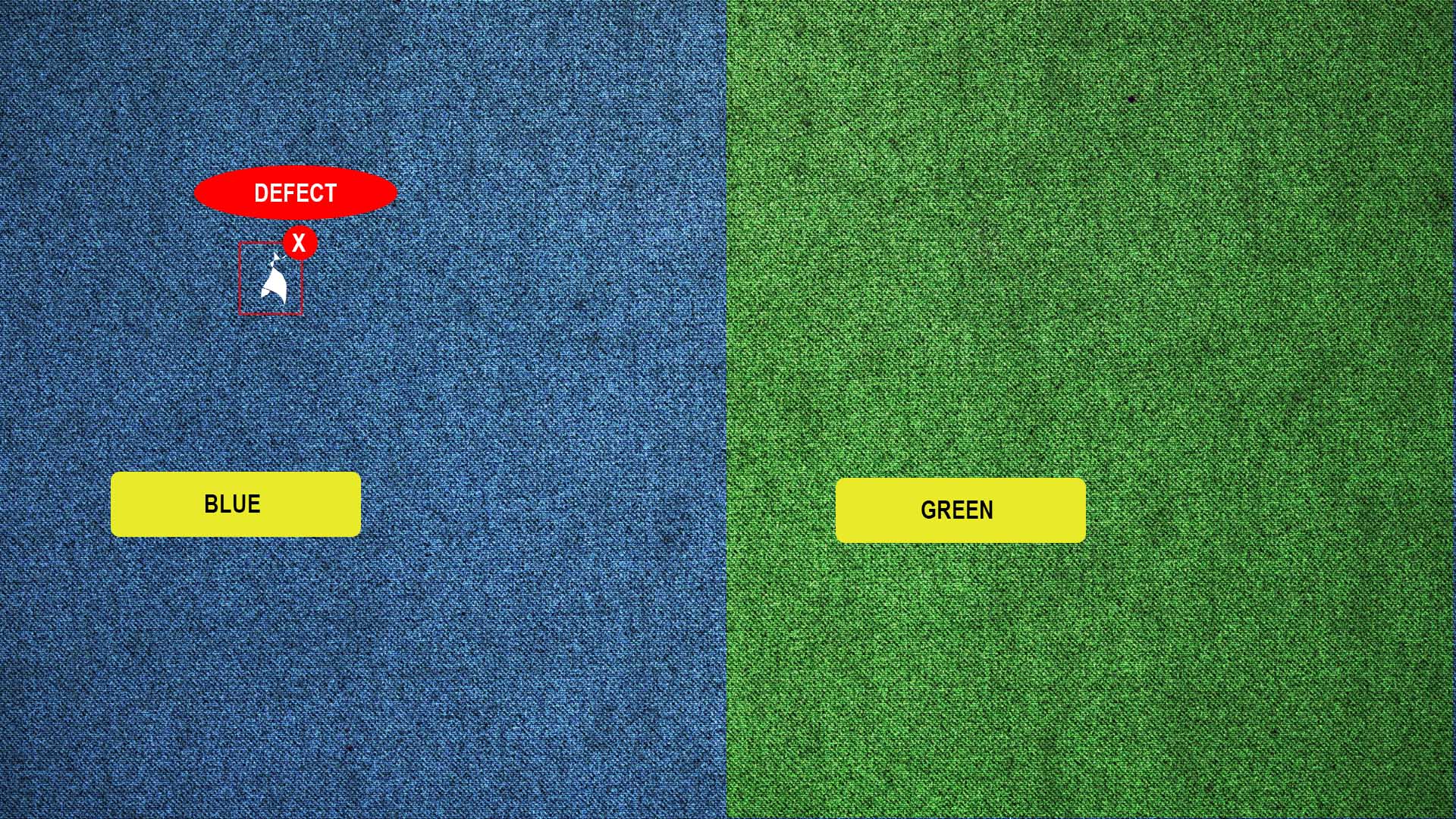

Textiles

The implementation of automated visual inspection, along with a deep learning approach, can detect issues of texture, stitching, weaving, and color. The manufacturer can initiate appropriate actions before the finished products reach the market.

Conclusion

Manual inspection of product quality is time-consuming and labor-intensive. It can be inconsistent leading to rejections and product recalls. This increases costs and wastage. Machine vision solutions developed by Qualitas Technologies minimize human intervention and automate, and optimize your quality processes. Businesses can achieve their goals of higher efficiency, reduced costs, minimization of wastage, and better customer satisfaction with our machine vision-based defect detection techniques.

Get In Touch With Us