By now, we all are aware of the benefits Industry 4.0 promises to deliver. Industry 4.0 is an umbrella term that refers to the numerous developments happening in the industrial value chain process. These changes are primarily powered by emerging technologies, especially the cloud, offering a better way to organize and manage all standard processes within the manufacturing industry. These include critical processes such as prototyping, development, production, quality assurance, logistics, supply, etc.

In short, it comprises all the extensive automation and computerization companies now deploy into their systems to improve their production cycles and connect all the different works aspects into a unified digital ecosystem. The wider uptake of Cloud technology in Industry 4.0 will play a pivotal role in enabling your organization to be more immersed and comfortable with digitalization. A Cloud Computing enabled manufacturing process facilitates a real-time exchange of data, creating and promoting an environment of digital collaboration and integration. At Qualitas Engineering, we are a strong advocate of the cloud.

However, you may ask, how exactly does cloud integrate with machine vision? What is its relevance when it comes to your machine vision applications? In this blog, we will discuss how cloud and machine vision can work in tandem to administer a powerful solution for your requirements.

Related Article- Machine Vision in Defect Detection Activities

CLOUD AND MACHINE VISION

Practically speaking, Cloud is not a new concept in the manufacturing industry. You may already be using the cloud for applications like a cloud-based inventory management system (IMS) and ERP systems. These systems generate data sets over time that tend to show patterns, making it possible for you to anticipate shifts in demand. You may probably be using the cloud to store sensor data or to perform tasks like data analytics. Nevertheless, where is it actually used in machine vision?

There are three possible uses, which can really augment your machine vision solution:

1. Images Backup

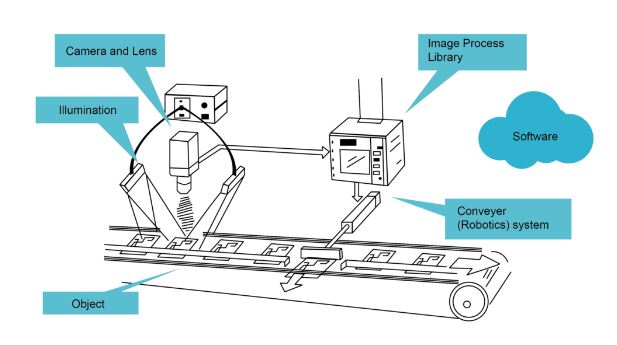

As long as machine vision has been around, it has been characterized by copious amounts of image data, which are captured, processed, and analyzed.

So maybe you have your machine vision system at the end of your production line to capture images for defect detection. Your vision systems may be capturing thousands of images every day. Storing these images can be very useful for future traceability and root cause analysis. However, as data flow increases in size and number, it is conspicuous that your local data storage solution may prove to be inadequate. The cloud is your best bet to back-up these images. The elastic nature of the cloud allows you to have virtually unlimited storage for your data at a fraction of the cost. This use of the cloud for image backup of your machine vision system ties in directly to the next use case.

2. Grading Workflow & Verify Accuracy

Another very useful application of cloud is to integrate it into your machine vision workflow to increase its effectiveness and enhance its capabilities. At Qualitas Technologies, we have developed a system that allows your backed-up images to be accessed by a human grader. Accessing these images, your grader can then verify the effectiveness of your system by checking whether the system has judged the images correctly or not.

This can be crucial to your system because your machine vision system is essentially a black box. There is no way to quantify the accuracy of your system directly. Using the cloud-based application developed by Qualitas Technologies, you can inspect a subset of images and verify that the system judgement and human judgement align. This allows you to measure the system accuracy objectively.

3. Model Training and Computation

The most common techniques used in machine vision are classification, object detection, and segmentation. All of these techniques are essentially different problem types of deep learning. Training these deep learning algorithms for your system requires a lot of computational power. Expensive hardware like a GPU is required to train your models efficiently and within a reasonable amount of time. If you wished to get your own GPU for training purposes, something like an NVidia Tesla V-100 GPU will easily cost you an upwards of $20,000. This GPU is designed to train deep learning models that are exponentially growing in complexity, in a practical amount of time.

All this computational power can be accessed for a fraction of a cost with services such as Amazon AWS or Microsoft Azure. Cloud computing is one of the major reasons to consider the cloud for your machine vision systems.

While there are many more potential uses of cloud computing in machine vision systems, the aforementioned points are the major use cases.

CONCLUSION

Ultimately, Industry 4.0 is a transition that is driven by customer demand and technological advancement. Industry 4.0 will continually be worked towards and the competitive landscape of each market will produce different paces for each industry. Cloud is a technology that is central to this revolution. The ultimate goal of integrating machine vision and cloud is to make the process simpler and cheaper. At Qualitas Technologies, we believe that this integration allows you to take away the challenges of machine vision and lets you focus on your product. At Qualitas Technologies, we help you get started with your machine vision system.

Register For Our Upcoming Free Webinar

I like the valuable facts people offer your posts. I’m going to bookmark your web site and have a look at all over again listed here regularly.