For over 30 years and more than 700 employees, our client has been leading the creative revolution in printing and production for automotive, electronics and appliance industry. They have been creating automotive dials, climate control overlays, exterior decals, logos, and badges for the world’s leading manufacturers. And we have earned their trust through a commitment to innovation, stringent quality checks and first-in-industry processes.

Trial Report

Problems faced by our client:

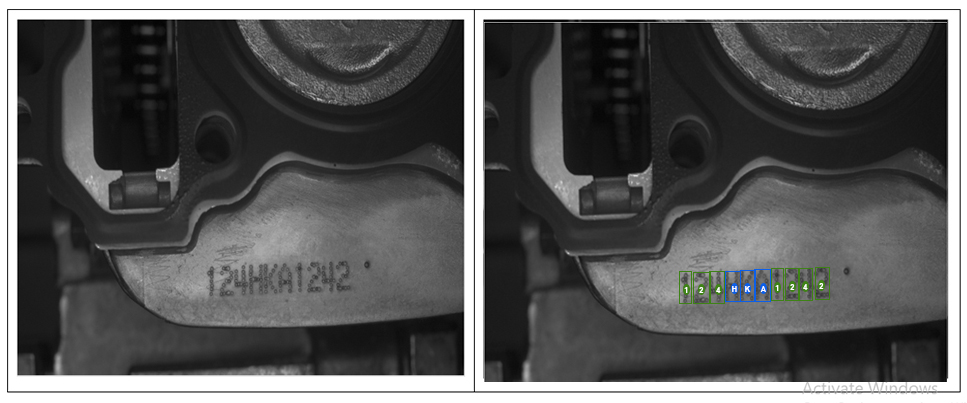

- Online reading of characters on engine part.

- Production line.

- Manually checking the defects was a tedious and error prone task.

Technology introduced by Qualitas Technologies:

Artificial Intelligence & Deep Neural Network which helps in optimal decision making and generating accurate results of Image processing. Compared to traditional OCR algorithms, AI-based OCR is far more accurate, resulting in 100% accuracy. Not only is it more accurate, but it’s very easy to maintain and update when new characters and letters are to be added to the recognizable character list.

Our solution:

- In the proposed system, the engine comes on the conveyor, the presence of the engine block will be sensed by the sensor and a trigger is generated for image acquisition.

- On image acquisition, the acquired image will be processed and OCR operation is performed to read the characters printed on the tube.

- The read characters are displayed in the Qualitas System GUI.

- Result (OK/NOT OK), is sent to PLC by the DIO module present in the vision system controller.

Conclusion:

The proposed solution will work for all the variants.