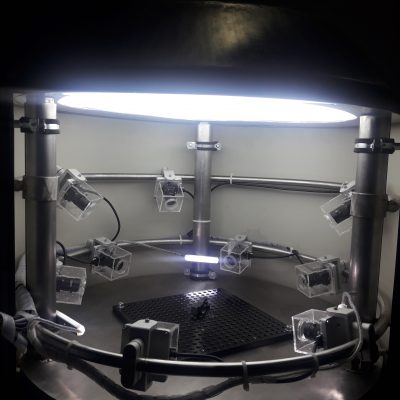

A common quality parameter that spans industries is surface finish quality. Whether it is an automotive part or a precision engineered tool, surface quality is key to maintain it’s functional and visual appearance. However, that is one which is done mostly as a manual process. As a result of manual decision making, quality is inconsistent. For that reason, Qualitas has developed a machine learning solution for identifying these defects. Consequently, Deep Learning and Artificial Intelligence Technologies offer high consistency and accuracy in decision making.

This advanced inspection systems use Artificial Intelligence for teaching and training the system for defects with a human-like approach. Imagine that you’re trying to teach a quality inspector on what anomaly constitutes an unacceptable anomaly and what constitutes an acceptable anomaly; you will teach them by using examples. Training this system would be very similar to that, and just as easy.