OVERVIEW

What are conveyor chains and why are they important? The conveyor chains are used to drive the conveyor belts. These chains are subjected to varying load (~15 Tons) and speed (65 feet per minute) which may cause cracks on them. In order to make it work efficiently, the chains need to be free of cracks.

Why do you inspect conveyor chains? – Any crack on the chains will lead to link breakage and eventually cease manufacturing operations.

WHAT PROBLEM NEEDS TO BE ADDRESSED?

There is no mechanism in place to identify the cracks on a moving conveyor.

HOW IS THE PROBLEM BEING ADDRESSED CURRENTLY?

The inspection of the chains is completely manual and only possible when they are stationary. Once the crack is identified, the operators replace the chain.

WHY AUTOMATION IS NEEDED?

To early identify the cracks on the chains in order to reduce the downtime and attain high throughput.

HOW CAN A VISION SYSTEM AND AI SOLVE THIS PROBLEM?

The development of the solution consists of 4 important parts i.e. Image Acquisition, Machine Learning, Solution Deployment, and Accuracy Improvement. Let’s understand in detail –

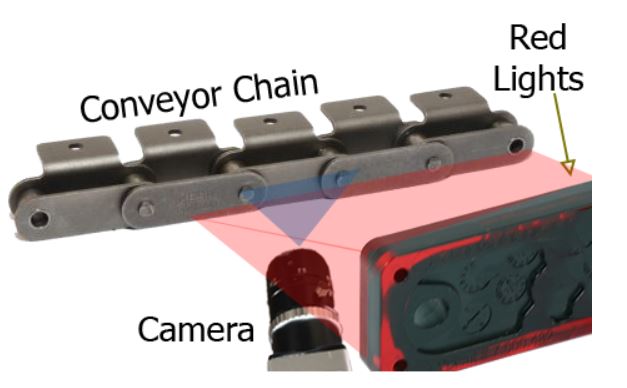

The image acquisition setup includes a camera with red line lights to illuminate the surface of the chains with minimum reflection. The setup helps in data collection i.e. acquiring the images of the links/chains.

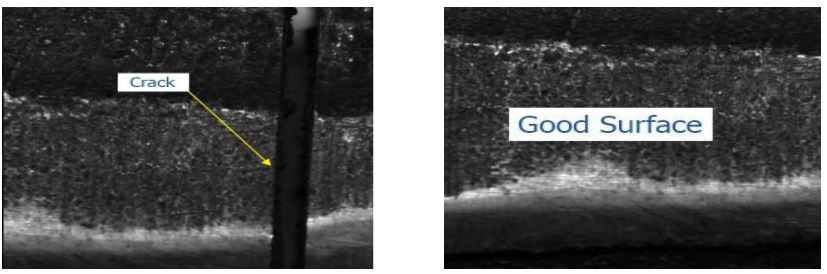

The machine learning part comes after the data collection. It is also called data annotation where images are used to train the AI-based model with the help of annotations (bounding boxes)

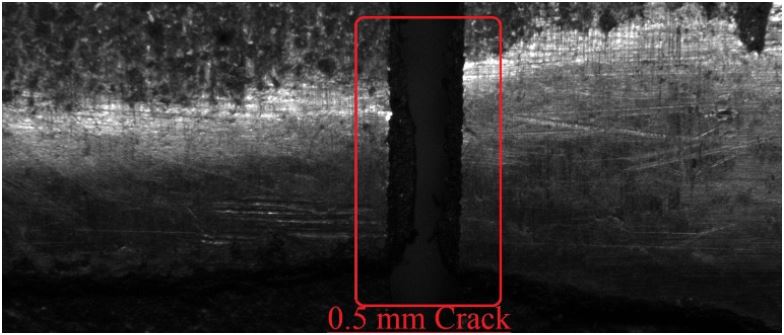

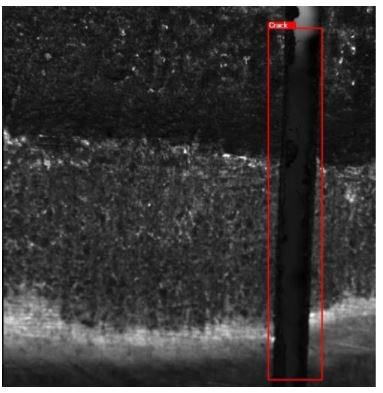

The trained model is then deployed at the live production line to check for the presence of the cracks in real-time.

In an ideal scenario, not all defects (cracks) look the same every time. There may be a few defects that are not pre-trained. Therefore, accuracy improvement is required and done by retraining the model until all variations are trained to ensure no unprecedented cracks are missed.

A pretrained library for ‘surface anomaly detection’ is used to identify cracks on the links of the chains

WHAT POTENTIAL BENEFITS CAN BE OBSERVED?

As per POC demonstrated, the following benefits can be realized:

- Cracks of a minimum 0.5 mm size were identified with more than 96 percent accuracy

- The average cycle time was reduced from 5 seconds per link to 3 links per second

- Manual intervention was replaced with automation that resulted in consistent progress