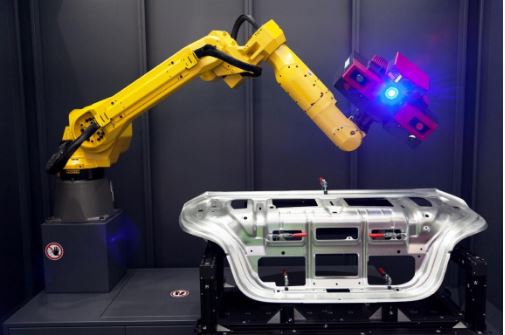

Machine Vision has gained massive popularity in dynamic industries such as retail and manufacturing within the past few years. These industries are leveraging the technology to enhance their customer experience, optimize the usage of resources, and achieve better quality assurance. Qualitas Technologies have been an advocate for this technology ever since our inception.

Your machine vision model accuracy is one of the most important factors that can help make your product successful and reliable in the market. The efficiency of your machine vision system is at the core of your production efficiency. The speed and overall throughput of your manufacturing processes are often dependent upon the speed of your machine vision inspection system.

However, do you still find your machine vision system to be inaccurate and inefficient? Does your system work great in a lab with samples but fails to meet the accuracy requirements on the production line? One of the faults you might be making with your system is building the system in a lab and trying to port it directly to your manufacturing environment. The reason this approach fails to produce desirable results lies in your image acquisition process.

WHAT IS IMAGE ACQUISITION AND WHY IS IT SO IMPORTANT?

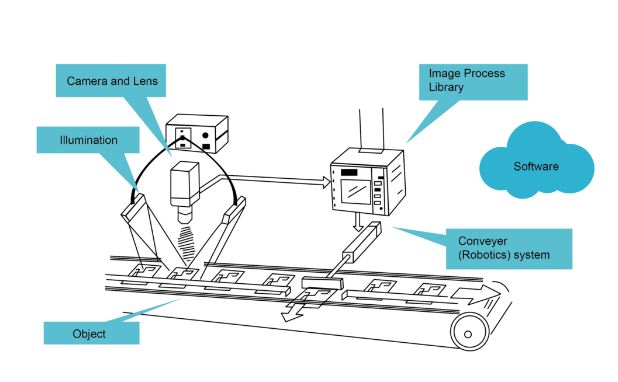

In image processing and machine vision, image acquisition is the action of retrieving an image from a source, usually hardware systems like cameras, sensors, etc. It is the first and the most important step in the workflow sequence because, without an image, no actual processing is possible. The image that is acquired by the system is usually completely unprocessed.

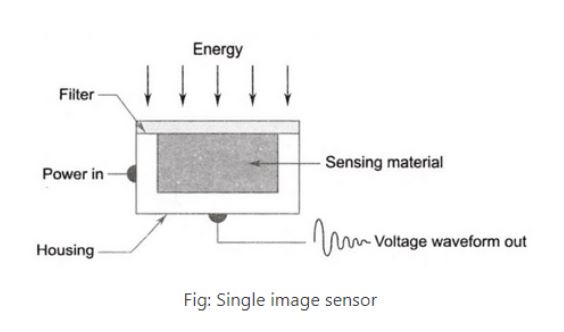

In the image acquisition process, incoming light energy from an object is converted into an electrical signal by the combination of sensors that are sensitive to the particular type of energy. These minute systems work together to provide your machine vision algorithm with the most accurate representation of the object.

The goal of the entire image acquisition process is to create an image that is usable by the machine vision technology. The imaging system’s quality is largely responsible for the success of your machine vision system. While the sensor system and cameras mostly rely on the technology available, there is one more parameter in the process that you have complete control on – the illumination of the scene. Keeping that in mind here are some fundamental, but quick fixes to improve the efficiency of your machine vision application.

PRACTICAL TIPS FOR MACHINE VISION EFFICIENCY

We have two major tips that will produce the best improvements in your overall results:

1. Lighting Techniques

In your machine-vision system, your lighting should provide uniform illumination throughout all the visible object surfaces. The illumination system should be set up in a way that avoids glare and shadows. Spectral uniformity and stability are key.

You should also take into consideration various factors like ambient light, daytime, etc. Between techniques such as backlighting, bright field lighting, grazing, low angle linear array, and darkfield lighting, there are several different ways you could illuminate the same scene. One major criterion you could consider to choose the adequate system is contrast. Techniques that demonstrate the highest contrasts will significantly help in increasing the efficiency of your machine vision system. At Qualitas Technologies, we provide proper guidance for the setup of your systems.

2. Trigger Range Function and Consistent Camera Triggers

Considering the efficiency of your camera triggers is also a crucial step that could greatly boost your overall system efficiency. This is especially true if you have moving parts. Keeping the triggers consistent with respect to the position of the object in the scene is decisive in these situations.

Sometimes, your industrial setup will create unwanted noise and cause false triggering of your inspection system. This could have numerous undesirable consequences on the quality assurance process, such as the software concluding that passable objects are failing inspection. Implementing a trigger range function and controlling for the length of the trigger signal, to maintain the integrity of machine vision systems is essential.

The aforementioned tips will help you achieve the best results with your machine vision system. At Qualitas Technologies, we provide all our customers with proper setup guidelines to achieve maximum accuracy. Additionally, here are some extra steps that could further help your system:

The aforementioned tips will help you achieve the best results with your machine vision system. At Qualitas Technologies, we provide all our customers with proper setup guidelines to achieve maximum accuracy. Additionally, here are some extra steps that could further help your system:

3. Light Wavelength and Frequency

Some parts, especially metal products, may arrive at your facility with some other material on top of them like a light coating of oil. This may create unwanted noise in your images. Adjusting the wavelength and frequency of light may help combat this issue.

4. Filtering

The industrial environment and factories often introduce the background and/or overhead lighting noise into your image acquisition system. This can be overcome with the correct wavelength of the lens filter, improving the accuracy and quality of image capture.

CONCLUSION

Machine vision systems, like developed at Qualitas Technologies, work best in inconsistent and undisturbed environments. However, this is not usually possible in an industrial setting. The aforementioned steps are simple and quick fixes. They will help you improve the efficiency of machine vision inspection, which improves the efficiency and throughput of the overall production system.

Contact us at Qualitas Technologies to learn more about how you could increase your machine vision system’s efficiency.

Register For Our Upcoming Free Webinar