If you are working in the manufacturing business, you have undoubtedly given a thought to the product quality. It is no secret that with intensive quality-control measures in place, your products will begin to reach higher and higher qualities, which has numerous benefits for you and your company.

High quality inspires brand loyalty, ensures compliance with regulations, conserves your resources, reduces risk, and allows you to become confident and consistent – all while assuring customer satisfaction. However, quality does not come without its cost. 100% quality assurance requires a lot of investment. Interestingly, these costs are not always in agreement with what you might estimate them to be.

HIDDEN COSTS OF QUALITY ASSURANCE

Like most organizations, you might have in place reports to measure and track quality costs. However, existing reports usually track only visible (traditional) factors that affect the cost of quality such as:

- Rejected material

- Scrapped product or work-in-process (WIP)

- Rework costs

- Yield loss

- Warranty costs

- Quality control personnel

However, there is more to the complete cost of quality than visible in the initial costs. When a substandard quality event does occur, a complex series of events transpire that incur their own individual costs – the hidden costs. Since the impacts hidden costs have are not (usually) tracked, their overall impact on the costs may not even be fully understood. Some of the major hidden cost inputs include:

- Extra operational costs

- The investigation into causes of defects

- Disruptions to schedules

- Emergency procurement of supplies

- Expedited shipping

- Disposal costs

Additionally, it is important to note that even these costs do not account for intangible hidden costs such as potential lost sales, lost consumers, and the potential damage to your brand identity and reputation. The full cost of quality is the sum of traditional quality costs that are already estimated added to the hidden costs. Interestingly, the costs associated with hidden factors are often greater than the traditional costs that existing reports track.

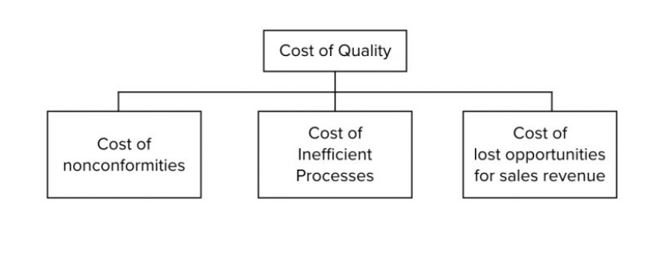

The Total Cost of Quality can be divided into four major categories:

- Internal Failure Costs – Represent all the costs of deficiencies before the delivery of a finished product to a client.

- External Failure Costs – Represent all the costs of deficiencies after the delivery of a product to a client.

- Appraisal Costs – Represent all the costs to determine the conformance/inspection costs of a product that has failed to meet a quality standard.

- Prevention Costs – Represent all the costs incurred to keep failure and appraisal costs in a manufacturing process to a minimum.

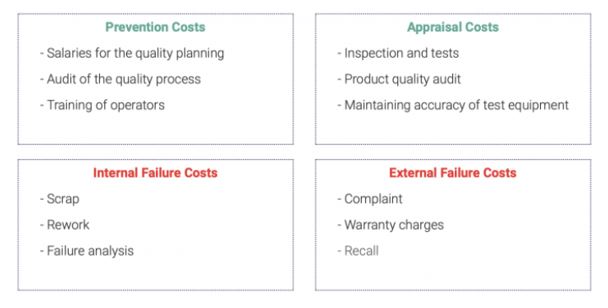

To understand this, let’s consider a manufacturing company producing parts for another car company. Here are some examples of how the cost distribution might look like.

Knowing these costs is imperative for proper management and contraction of Total Cost of Quality. However, as much as these distributions and knowledge help in eliminating costs and ensuring quality management, there is always going to be the scope of errors in your quality assurance chain. These liabilities are especially evident where your employees do the quality check physically.

All of these shortcomings can be avoided if you automate your quality check process, ensuring that no defective product ever leaves your manufacturing plant. But how exactly can you automate this critical process? The answer is Machine Vision.

AUTOMATION OF QUALITY CHECK PROCESSES USING MACHINE VISION

Machine Vision using technologies like Deep Learning have successfully made headway in solving automatic recognition of patterns in data, which has surpassed the ability of human beings. Over the past few years, deep learning and has successfully solved the limitations of numerous traditional machine-learning algorithms. As with any growing technology, during its period of growth, it has caught the eye of huge industries and businesses. One of the most widespread applications of this technology is the quality check process during manufacturing.

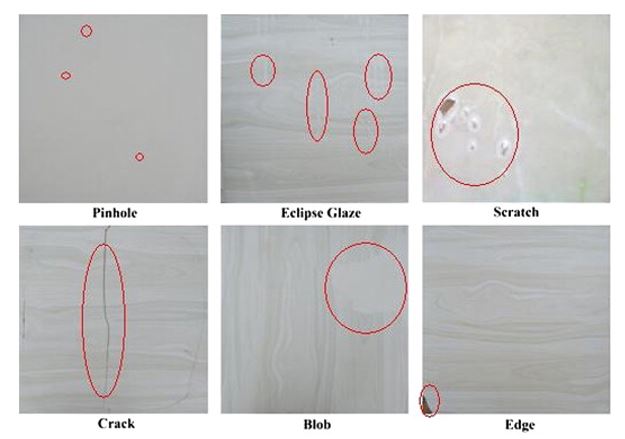

Techniques like segmentation work extremely well for quality check applications. Image Segmentation classifies individual pixels of an image. Image segmentation could involve separating foreground from background, or clustering regions of pixels based on similarities in colour or shape. Because segmentation analyses every pixel of an image, the algorithm can take images with large resolutions and detect a defect that may go unnoticed even to the human eye. Therefore, you can easily install cameras across your production and line, and use machine vision and deep learning applications to automate the process of defect detection with almost precise accuracy.

Automating and streamlining your quality check processes using the aforementioned technology can help you save many resources while simultaneously ensuring the attainment of the degree of quality you wish.

CONCLUSION

The technology of machine vision available at our dispense today is one of the most powerful inventions we have ever seen. Implementing such technologies can bring in never before seen possibilities for your business. We at Qualitas Technologies are here to help you do precisely that. Ever since our inception, our mission has been to enable the manufacturing industry to realize the possibilities of machine vision and artificial intelligence. Contact us to help you exponentially increase your product’s competitive and financial value using the technologies of machine vision and deep learning.

Register For Our Upcoming Free Webinar