Automated Inspection with the help of Machine Vision and AI Technology

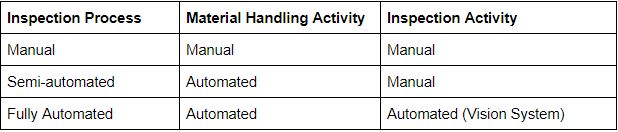

Industries all around the globe compete hard to deliver products of the highest quality standards. To maintain or improve competitive inspection standards the methodology of quality control must be made efficient. Automation is an essential part of this improvement process as dependence on humans or manual processes would weaken the quality control process. A product inspection is of utmost importance in mass production industries and is mostly done through visual inspection. In order to achieve a 100% inspection, the industries spend a lot on the inspection. Often random sampling is used for inspection. Visual inspection is commonly done in the following ways i.e manually, semi-automated, or fully automated. The current trend of quality inspection adopted by most of manufacturing companies is manual inspection.

2 Key Activities In Quality Inspection

- Material Handling – transporting the products manufactured along the manufacturing supply chain to the next set of value-adding processes/tasks

- Inspection – Which is the activity of visually inspecting the product/process for identifying defects.

Related Article: How to Improve Quality in Pharma Industry using Machine Vision

Manual Inspection

This is the least automated way of performing the inspection. The products or parts to be inspected are manually picked up and inspection is being done to identify various cosmetic defects like scratches, dents, burr, and other defects visible to the human eye. The performance of manual inspection is generally inadequate and inconsistent.

Why is Manual Inspection inefficient?

- Endless routine jobs

- Slow

- Inaccurate

- Ergonomic constraints

Also Read: Machine Vision is creating a new wave in the Automobile Industry

Semi-Automated Inspection

Semi-Automated Inspection utilizes automation for material handling and the manual operation here though is the inspection activity. Though there is an improvement from the manual inspection processes described above there still has to be constant coordination between the automation system and manual operator performing the inspection. If the speeds are high or if the human misses apart, defects can be missed and thus passed out to customers.

Related Article: How Can Food & Beverage Segment Benefit From Machine Vision Inspection

Fully Automated Inspection

In a fully automated system, the material handling as well as the inspection activity is automated. Many technology companies including Qualitas technologies develop cutting edge systems to automate the visual inspection process. Providing benefits like speed accuracy and traceability in the inspection process. Coupled with automated material handling, these systems can be fully autonomous reducing human dependence thus eliminating the errors that come with manual operations. Of late, AI technology has made significant strides in the computational aspects as well providing added advantage which was not available with earlier technologies.

Several practical reasons for automated inspection include:

- Matching high-speed production with high-speed inspection

- Higher accuracy

- Freeing humans from their monotonous job

- Lower expenditure on human labor

- Performing inspection in unfavorable environments

- No dependency on highly skilled human inspectors

Related Article: Integrating Machine Vision & AI with Toyota Production System

Machine Vision and AI Technology for Inspection

Machine vision focuses on image acquisition by various cameras with different resolutions. AI is used for image processing, where the software algorithms analyze the image to provide desirable results that match the preset inspection parameters. Machine vision and AI technology are increasing the speed and accuracy of the inspection process, thereby paving paths for new ways of improving quality aspects of the manufactured products.

CONCLUSION

Visual inspection has evolved from manual to automated. Humans are not designed for repetitive and low cognitive tasks, so errors are common when there is heavy manual dependence on such processes. Improving the inspection process with the help of machine vision and AI entails improvements in speed and accuracy of the inspection task. In addition to this, humans are freed from dull and routine tasks, providing an opportunity to repurposes them for higher-skill activities.

Register For Our Upcoming Free Webinar