We are in the era of Industry 4.0, where Industrial automation is one of the quintessential aspects of the manufacturing sector. Industries are looking forward to implementing changes that could be beneficial to them in terms of enhancing productivity, quality, cost, and other parameters. With the inception of Artificial Intelligence Machine Vision, Robotics, IoT, Cloud technology industrial automation is gaining momentum in the manufacturing industries.

Why choose a machine vision system?

The system caters to optimizing the production or assembly lines, minimizing human intervention in critical processes, enhancing the quality assurance, and improving overall throughput. All these lead towards better return-on-investments.

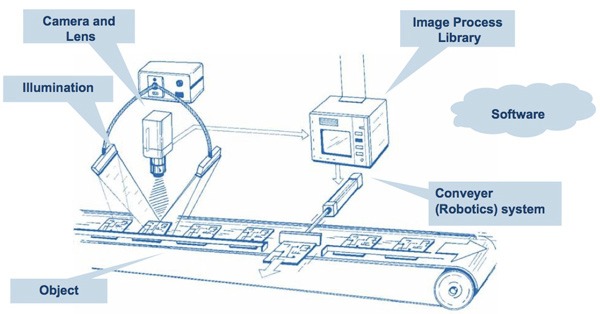

Before we could move towards applications, let us understand what a Machine vision system is all about. It is an integrated system with a combination of cameras, sensors, optics, and illumination as the hardware components and the computing units with deep-learning enabled algorithms. All of these are synchronized to fetch the required output/result.

Without a doubt, every manufacturing unit has a production & quality inspection section. Let’s see how it can benefit from the applications of machine vision. Owing to its adoption in the production line to pick and place the parts/objects, or in the quality section, machine vision plays an essential role. It solely lies in the interest of the manufacturer in deciding the application.

Related Article: 3 Machine Vision Applications Solved by Artificial Intelligence

Production:

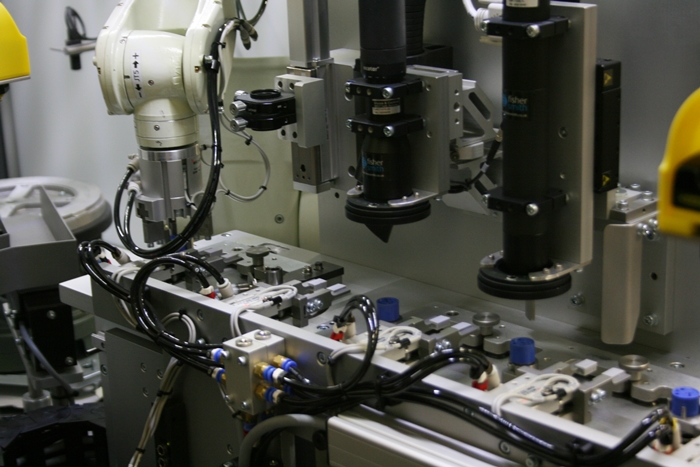

Most of the production lines run on repetitive tasks. The workforce is engaged to perform continually. Usually, the expected results include increased productivity, efficiency, and accuracy. Now take an example of the automotive industry wherein deploying vision-guided robotics for pick & place the parts and position them accurately. It not only allows in reducing errors prone to the manual process but also increases the overall efficiency of the production.

Another example would be the welding process. Here, accuracy plays a vital role in welding or joining two or three parts. It would be a real challenge for a laborer. But vision-guided systems can accomplish this task at greater ease.

The output achieved through this technology are:

- Increased productivity: performing repetitive tasks resulting in decreased task time.

- Reduced downtime: A comprehensive training of the vision-based system is offered by providing sufficient samples & variants. Hence, after introducing it to the assembly line, machine downtime is negligible.

Accuracy: Replacing human intervention in some of the critical processes significantly increases the accuracy

Also Read, Machine Vision Trends in 2020

Quality:

Quality products are a symbol of business excellence. In addition to this, they are one of the factors for reliability and customer satisfaction. Most of the manufacturing units still have manual inspection processes, that have increased the error rate and has impacted the production cost. Identification of defects or damaged parts in prints, fabrics, and another anomaly testing, can be efficiently handled with quality control image processing or machine vision solutions and systems.

Let’s take an example of gauging/measuring the machine parts like brakes, piston rings, etc., in auto and auto ancillary industries, where there is a mass of products. The products are measured against the set standard values, where manual inspection would be error-prone. The vision-enabled systems can measure the parts that are beyond the ability of the human eye.

How machine vision is bringing transformation in quality:

- Reduction in scrap: Implementing machine vision systems and solutions at different phases of the process can reduce wastage

- Increased accuracy: Precision controlled quality checking system significantly increases accuracy

Related Article: COST OF QUALITY

Cost:

Some of the factors that add as a cost to manufacturing units are labor, machine downtime, training labor, and quality testing enhancements, which can be minimized with the use of machine vision systems.

Here’s a list of machine vision & solutions associated with the manufacturing industry.

- OCR

- Defect Identification & Inspection

- Label Inspection

- Engine parts presence or absence identification

- To check the orientation or alignment of the objects/parts

- Packaging – primary & secondary inspection

- Vision-guided Robotics & Automation

According to one of the surveys, industrial automation will surely be the trend in the coming days. With the pandemic stretching out every nook and corner, it has temporarily stalled the functioning of the industries. But, many manufacturing industries right from automotive, food & beverages, pharmaceuticals, textiles, consumer sector and others are planning to outdo the traditional methodologies and replace them with automation systems. In conclusion, machine vision and robotics coupled together can create new trends in the manufacturing industries.

Register For Our Upcoming Free Webinar