Simplify & automate parts counting with precision – from small parts to large packaging materials

Automated Parts Counting - Industrial Automation

Our Solution Uses Deep Learning For Automated Parts Counting.

Our Proposed automated parts counting machine uses machine vision which is widely used in various industries and helps in solving all the productivity-related problems and at the same time meets the customer’s expectation. Currently, the company has deployed many machines for counting parts.

Our solutions are running successfully across a variety of different industries and applications. Some images are shown as illustrative examples below.

Automated Counting Using AI Vision System

Automated Parts Counting

Qualitas has developed a visual inventory tracking system that can automate counting of the products based on images.

Piston Ring Counting

This machine is used to count piston rings and can count 20 + different models of rings ranging from a minimum thickness of 0.25mm.

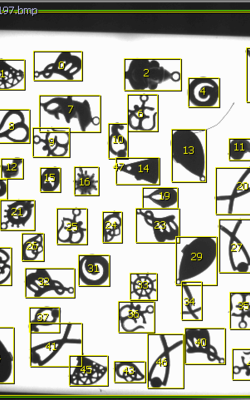

Jewelry Counting

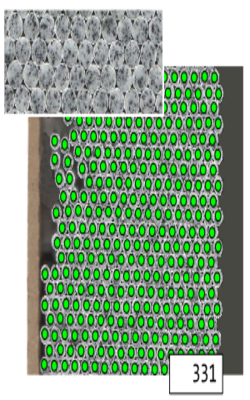

Vial Counting