Visual Inspection in Food Industry

Visual inspection, as the name suggests, is a process of quality assessment. In the manufacturing process, this determines whether the products meet the desired standards. The inspection process is very crucial as it determines the final products delivered to the customers. An automated inspection helps in ensuring safety. Any company ought to ship only non-contaminated safe products. The uniformity of containers is also checked through this process to deliver products of equivalent quality. Packaging defects are also easily spotted and corrected. Furthermore, the misprints in labels, if any, are also corrected. Vision inspection helps maintain the brand value by ascertaining any defects in items and improvising upon them.

Pizza Quality and Missing Toppings

In the ever-expanding food industry, pizza is one of the evergreen favorites. With a multitude of new varieties, its demand is now surging even higher. It would then be a disappointment if an order does not live up to the customer’s expectations. Pizza quality primarily depends on the dough, sauce spread, and toppings. Pizza toppings have always been a topic of great deliberation among the ardent foodies. One might prefer bell peppers, olives, meat, or even pineapples, for that matter. But the careful consideration of toppings falls flat if the supplier fails to provide enough quality or quantity. The most popular brands have also faced complaints regarding insufficient or missing toppings. An integrated intelligence system for fast-food inspection can then come to the rescue in such cases. An efficient cent percent quality check would ensure that the customers wholeheartedly enjoy their meal.

Machine Vision for Pizza Topping Inspection

Machine vision is an advanced technology gaining momentum in recent times. It essentially refers to all applications that capture and process digital images for the better functioning of devices. Its humungous benefits have also impacted the fast-food inspection industries. Earlier, piece counting demanded immense efforts, time, and labor. Machine vision has drastically cut down these requisites while simultaneously improving the food quality inspection. This also proves to be cost-effective due to the manual training and bulky setups being eliminated. Also, the probability of human error was much more in the repetitive counting process. It has now been replaced with advanced technologies resulting in much higher accuracy and efficiency.

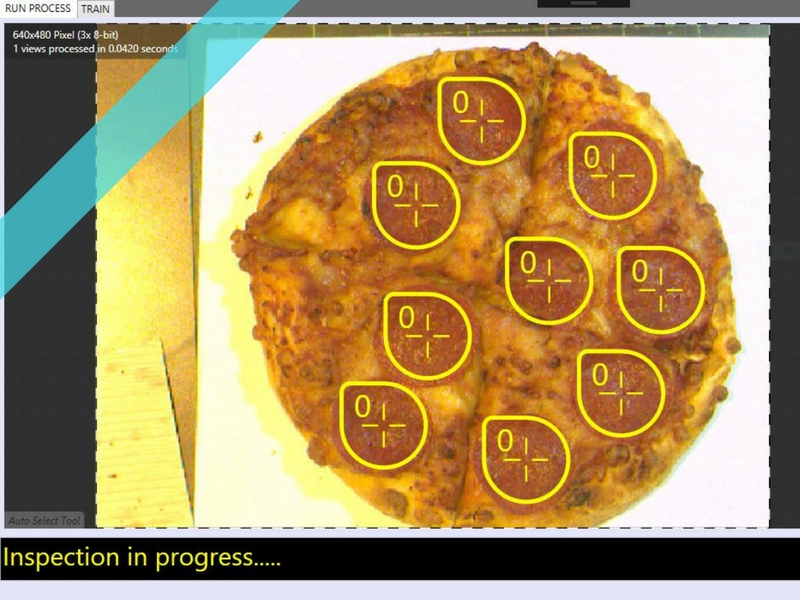

The number of toppings and their distribution both were analyzed through a region-based segmentation. The similarity of distribution was checked by dividing the pizza image into segments of equal area. The experimental statistics are proof of the effectiveness of machine vision in food quality inspection. This is suitable for a wide range of pizzas and has an accuracy of more than 90% in determining the quantity and distribution of toppings.

Accuracy of Machine Vision in Counting Toppings

Machine vision has drastically improved the accuracy of food quality inspection. Considering the soaring demand for pizzas, it is obvious that the same recipe has to be replicated a multitude of times. The prior process was excessively time-consuming and led to inaccurate counts of toppings and calories. This was bound to impact the brand image and restaurant ratings adversely.

However, the fast-food inspection process was then successfully automated. The capturing and processing of images lead to desired results. The setup helped in successfully performing a proof of concept (POC). The overall quality of pizza toppings depends on two main factors- number and distribution. For this reason, the primary objectives of the solution were also dependent on the same. The segmentation technique helped in counting the calories in the entire pizza and then replicating it. The topping count is performed through the module of object detection. This method ensures the same number of toppings on all pizzas and hence removes unevenness in distribution. This accurate count also guarantees that the pizza prepared by the head chef and assistant chefs are of the same quality.

The Qualitas Solution

We at Qualitas have always stayed true to our vision of facilitating industries through Artificial intelligence and machine learning. As per the current fast-food inspection needs, we have launched yet another economical product. Part counting through deep learning is of tremendous help in food quality inspection. The Qualitas Eagle Eye incorporated basic steps to reach the outcome. Firstly, the camera installation took place for acquiring the food image. Then the concepts of deep learning and AI were brought into application. Subsequently, the model was then analyzed for any scope of improvement. Finally, necessary changes were made to suit the customers’ needs.

The setup processes the image of a pizza and assesses its toppings. For instance, in a pepperoni pizza, the total count of pepperoni slices is shown. Similarly, we have used the setup with various other toppings like mushrooms and olives. Real-time counting takes place, and the number of toppings fluctuates if one manually adds or removes slices. Machine learning ensures that the pizza quality is not compromised and the counting process is made considerably easier.

Conclusion

Pizza is undoubtedly one of the most popular fast foods. High availability in choices also results in competition between food companies. An accurate food quality inspection becomes a must to increase the customer base. Manual counting was tiresome and also massively prone to errors. The introduction of deep learning to regulate pizza quality has been of huge relief. The object detection technique has been statistically proven to be highly accurate. It makes sure that all pizzas by a supplier are of the same quality and contain an identical number of toppings. This also improves the restaurant reviews while satisfying the customer’s requirements. Moreover, It also guarantees value for the consumers’ money. Machine Vision and Artificial Intelligence indeed have a very favorable future in the fast-food inspection industry.

Sir , Can you give me the code of Pizza Topping Inspection Using Deep Learning?