Our client is a fully integrated flat carbon steel manufacturer based in India– from iron ore to ready-to-market products – with a current capacity of 10 million tonnes per annum (MTPA). Their steel manufacturing facility comprises ore beneficiation, pellet making, iron making, steel making, and downstream facilities including cold rolling mill, galvanising, pre-coated facility, steel processing facility, extra wide plate mill and a pipe mill.

Problems Faced By Our Client :

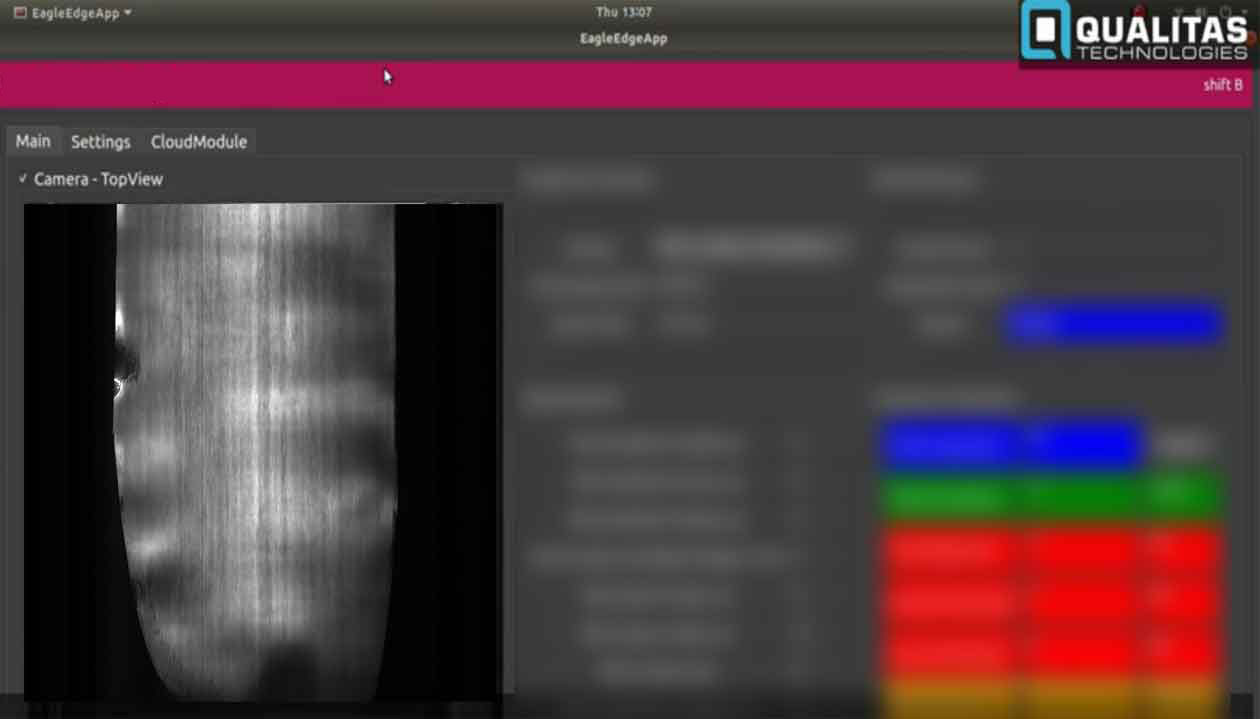

- Examining surface defects on hot steel strips inside their factory’s CSM (Compact Strip Mill).

- Each strip has a temperature of 600 to 900°C, making the inspection process extremely difficult. For more details, please fill the form and download case study.!

For more details, please fill the form and download case study.