Our client is one of the largest Korean multi-industry companies that produces electronics, chemicals, and telecommunications products in over 80 countries. They control a big portion of the electronics market worldwide and since 2008, they remain one of the world’s top 5 LCD television manufacturers. The company has 128 operations worldwide, employing 83,000 people.

Problems Faced By Our Client :

Automated OQC Check Sheet/Report Generation which consists of a combination of checkpoints checked using:

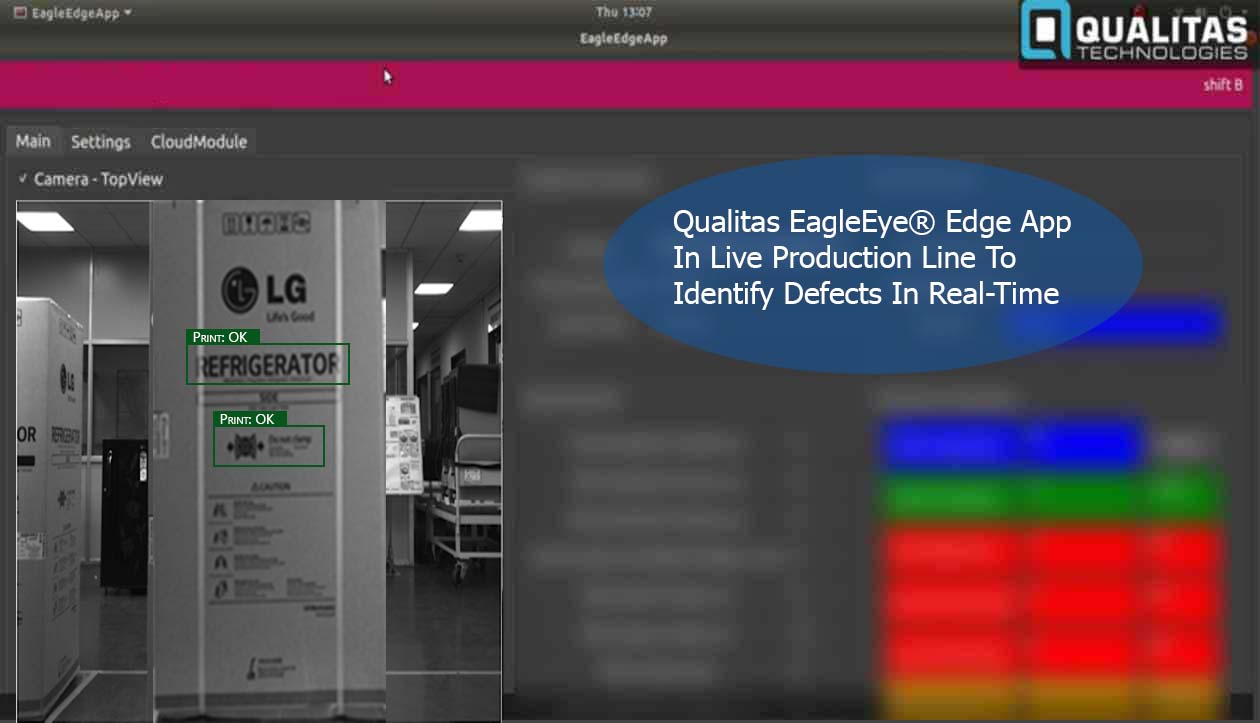

●Machine Vision: Printing/Component Presence/Absence inspection.

●Barcode Verification: Verify the Barcodes present in Carton Box and Machine and whether it matches the expected barcode.

●Manual (Visual) Inspection – Manual Entry to be made in Software.

The current process was done manually since it was time-consuming, they wanted to minimize the inspection time and that’s why they opted for the vision system.

For more details, please fill the form and download case study.

Hello, constantly i used to check webpage posts here in the early hours in the morning, for the reason that i love to find out more

and more.