Case studies> Oil and Gas > Automated Bottling of Liquid Petroleum Gas (LPG)

Automated Bottling of Liquid Petroleum Gas (LPG)

By – Raghava Kashyapa

Published on – 04-09-2022

The customer is one of the three largest distributors of portable LPG cylinders, used for cooking by a vast majority of Indian households. Throughout the country, there are numerous cylinder filling stations where empty cylinders collected from households are refilled with a measured amount of LPG and delivered to depots. Qualitas has successfully implemented AI-based automation in critical areas of the labor-intensive, hazardous, and an error-prone cylinder filling process.

Problem Definition

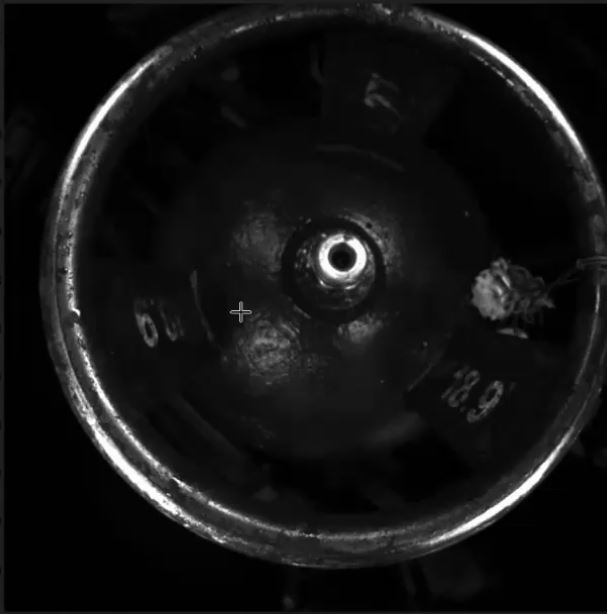

The empty cylinders moved sequentially along the refilling line. As each cylinder approached the filling station, a human employee was required to visually inspect two numbers inscribed on the cylinder body (FIG: 1). First, the empty cylinder weight and second, a date code. The date code was read and recorded to determine if a periodic pressure test was due for that particular cylinder.

Fig – 1 (The top view of a typical LPG cylinder showing the characters to be read)

Multiple instances of these two numbers were stencil-painted onto the upper surfaces of the cylinder. The filling line would temporarily stop so that a human employee could glance into each bottle, decode the two numbers, and input them into the system. This procedure was inefficient, and necessitated the presence of a human worker in a potentially hazardous environment, posing a safety concern.

Solution and Implementation

Qualitas automated two processes. Initially, at the cylinder filling point, a high-resolution camera and a high-intensity light source were first installed. As each cylinder passed by, the camera and light were triggered to fire on its top surface. The captured image (FIG: 2) was processed using the Quality EagleEye Platform (QEP)’s Deep Learning software. Image segmentation was initially used to count the number of inscription locations on an image. Then, using a specially designed (and later patented) Optical Character Recognition (OCR) software, the two numbers were deciphered and fed into the system. Because the numbers were imprinted in multiple locations, it was possible to read, interpret, and confirm the figures multiple times, thereby increasing the level of confidence, especially in difficult-to-comprehend cases (FIG: 3, FIG: 4).

FIG-2 (Camera image of a cylinder top view. Characters to be read are “15.6” and “B 26”)

FIG- 3 (A hard to read case: The cylinder is old and grimy)

Fig – 4 (A hard to read case: Reflections off a a new and shiny cylinder)

A similar camera and illumination system deployed further down the production line was utilized to record a top image and validate that each cylinder’s filling nozzle section was fitted with a vital safety cover. This was accomplished using the QEP’s object detecting feature.

Conclusion

These two relatively simple automations of human labor had a significant positive impact on both productivity and safety. After automation, the number of cylinders processed per minute increased from 12 to 40. Number reading precision increased from 90% to 97%. Losses resulting from cylinder overfilling and under filling were significantly reduced. Employee exposure to dangerous conditions was almost entirely eliminated.

The customer predicted that this automation would result in yearly savings of around INR 3.6 million per filling line. In a span of two years, the number of filling stations across the country is expected to approach 60.