Machine Vision Applications In Industry

Machine vision technology aims to integrate existing technologies in novel and innovative ways and apply them to solve real-world problems. It tries to meet the requirements of manufacturers and continually improves itself to conquer newer areas of work.

This field encompasses many technologies, software and hardware, and integrated systems in industrial automation applications.

Some common uses of machine vision applications are –

- Engine part inspection

- Labeling, packaging, traceability, and barcode inspection

- Checking medical devices for defects

- Checking orientation and verification of components

- Checking laser marks and cuts

- Robotic guidance for quality control checks

Related Article– 7 APPLICATIONS OF MACHINE VISION

Did you know machine vision technology is also used in these industries?

- Space industry

Satellites can provide information on land coverage classification, crop yield prediction, crop and soil maps, water and soil pollution maps, and land development management and analysis.

- Agriculture

It is used in harvesting, pruning, monitoring, and pollinating.

Also, Read Make The Best Use of Machine Vision in Agriculture

- Sports

It can replace broadcast cameras, track objects and players, and perform game and player analysis.

- Pandemic management

Faster and distant body temperature measurement, disinfecting rooms with robots that use UV rays, mask detection in a crowd are also possible through machine vision.

- Military

2D vision systems and other equipment can be used to enhance surveillance systems, run autonomous vehicles for unmanned reconnaissance. It can be used for the removal of landmines and quality control in ordinance manufacturing.

- Transport

Security and vehicle guidance, improving safety and road traffic efficiency, reducing accidents with lane departure warning systems, pedestrian detection, driver monitoring, and more.

- Traffic organization

It can be employed in multilane vehicle counting, speed measurement, traffic monitoring, and manipulating traffic lights.

Also, Read Machine Vision Makes Its Mark On The Automotive Industry

Apart from these, there are more potential uses of machine vision applications. These are uncommon but pretty powerful. Let us, deep-dive, into some of them –

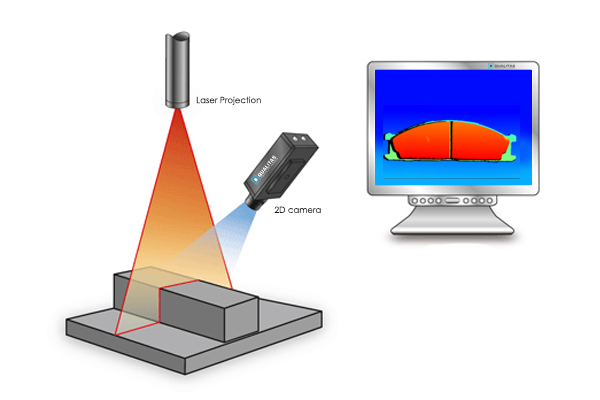

2D Camera With Laser Projection

3D machine vision systems use a projected light pattern consisting of a 2D camera aided by applying laser projection on a surface. Based on the depth or curvature of the surface the laser presents different patterns to the camera.

The most common method used in 3D vision systems is laser triangulation. A line laser is projected onto the surfaces of an object. The line is viewed by a camera from a different angle and the deflection of the line is based on the geometry of the object. Several profiles are generated during this process. A 3D image is created using these profiles. The multiple profiles ensure balancing deviations and rotation of objects across various aspects.

Applications and Uses

- Detection of defects in gas cylinders

- Application of laser projection can be used in quality checks of products.

- Bar code verification

- OCR value comparison

- Fresh produce spoilage

- Robot guidance systems

- Depalletization and anthropometry

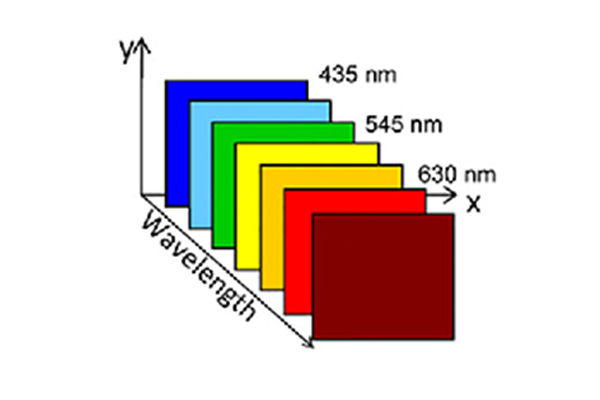

Spectral imaging

Spectral imaging works with the wavelengths of light that are invisible to the human eye such as ultraviolet and infra-red spectrum. It uses infrared cameras for multispectral imaging or hyperspectral imaging. These are specialized cameras that require a more sophisticated setup like dispersive optics and a line scanner.

Spectral imaging works with the wavelengths of light that are invisible to the human eye such as ultraviolet and infra-red spectrum. It uses infrared cameras for multispectral imaging or hyperspectral imaging. These are specialized cameras that require a more sophisticated setup like dispersive optics and a line scanner.

Hyperspectral imaging collects spectral information across a wide range of wavelengths at the same time as recording the spatial information in an image. Hyperspectral cameras can see patterns or compositions of material that are invisible to naked eyes. The greater information provided from these wavelengths, the more detailed chemical information is available to be mapped. This does require hi-tech instrumentation and more complex data processing.

Applications and Uses

- Detecting defects and contaminants

- Quality check of packaged material and packaging

- Enabling quality control and sorting of commodities

- Provides automated plant detection

- Differentiate closely related materials like types of plastics in recycling

- Sealing, coating, and sterility of products in the pharmaceutical industry

- Infrared cameras help pilots and drivers steer vehicles at night and in fog

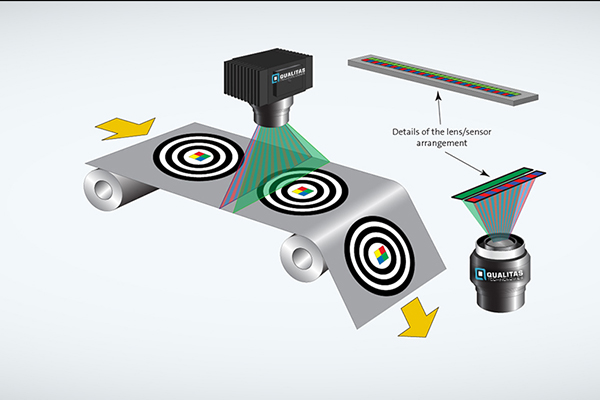

Line Scan Cameras

A line-scan camera can give a high-resolution image of large continuous objects and circular objects. It has a single line or a single row of pixels that is better than a frame camera. The camera or the object under consideration is moved in a perpendicular fashion to get a 2D image of the object. It uses a focused light from a line of LEDs, to illuminate the object along the line of object pixels being viewed. Colour line scan cameras are also available. They have sensor pixels with different colour filters to determine wavelengths.

Also, Read Area Scan vs Line Scan: What Fits You Better?

Applications and Uses

- Productive and efficient print inspection and perfect documentation.

- Grains and fruits inspection through optical sizing and colour sorting. Early detection of external or internal damage is possible.

- Tile quality inspection using two-line scan cameras guarantee uniformity and lead to an increase in the quality of tiles produced.

- Inspection of steel sheets, paper, textiles, metal, or glass inspection.

- Scanning PCBs, LCD panels, and wafers.

- Inspection of flat panel displays, solar cells, textiles, fibre and semiconductors. It helps in sorting or tracing posts and printed circuit boards.

- Measurement of components such as solder balls or pins.

- Medical equipment or currency inspection.

Conclusion

The market for vision systems is growing with the increase in automation and integration of machine learning and neural networks across industries. It can be integrated to take business efficiency and safety, and quality features to the next level.

Register For Our Upcoming Free Webinar

Outstanding post however I was wondering if you could write a little more on this topic?

I’d be very thankful if you could elaborate a little bit further. Thanks!

Thankfulness to my father who stated to me on the topic of this

blog, this weblog is in fact remarkable.

excellent submit, very informative. I wonder why the other experts in this sector do

not realize this. You must proceed with your writing. I’m confident, you have a great readers base already!

Good day! Would you mind if I share your blog with my Facebook group?

There are a lot of people that I think would really enjoy your content.

Please let me know. Many thanks

My spouse and I stumbled over here different web page and thought I should check things out. I like what I see so now i’m following you. Look forward to looking at your web page again.|

My partner and I stumbled over here by a different page and thought I might as well check things out. I like what I see so now i am following you. Look forward to checking out your web page again.|

Oh my goodness! incredible article dude! Thanks, However I am going through problems subsequent to your RSS. I dont comprehend why I am unable to member it. Is there anyone else having identical RSS problems? Anyone who knows the respond will you kindly respond? Thanks.

Hey There. I found your weblog the usage of msn. This

is an extremely well written article. I’ll make sure to bookmark it and return to learn extra of your helpful information. Thanks for the post.

I’ll certainly comeback.

Thanks for your marvelous posting! I genuinely enjoyed reading it, you’re a

great author. I will make sure to bookmark your blog and will come back later on. I

want to encourage you to continue your great writing, have a nice weekend!

Thanks in support of sharing such a fastidious idea, post is nice, thats why i have read it entirely

Then you may take the motherboard again out, place the

spacers, and put the motherboard in on high of them.

While an appointment may need a selected time limit, that doesn’t essentially mean the enterprise can accommodate two appointments again to back.

But replacing one or two parts, especially the oldest

part or the one you have determined is inflicting a bottleneck, can provide spectacular performance

improvements whereas remaining price efficient. It has

been a while since I cracked a pc open and explored its innards, however this endeavor has inspired me to,

at the very least, improve the RAM in my laptop.

Case, Loyd. “Tips on how to Upgrade Your Graphics Card.” Pc World.

Or would you like to use a graphics card on the motherboard to keep the worth and measurement down?

A nice midrange card can enormously enhance performance for

a couple of hundred dollars, but it’s also possible to find much cheaper ones that aren’t bleeding-edge that may fit your wants just fine.

I have to thank you for this article

Pretty component to content. I simply stumbled upon your blog and in accession capital to say that I acquire in fact enjoyed account your weblog posts. Anyway I?ll be subscribing in your augment and even I fulfillment you get entry to constantly fast.

I?d must examine with you here. Which is not one thing I usually do! I take pleasure in reading a submit that may make people think. Additionally, thanks for permitting me to remark!

Hi there, I found your web site via Google while looking for a related topic, your site came up, it looks good. I have bookmarked it in my google bookmarks.

I’m extremely impressed with your writing skills as well as with the layout on your weblog. Is this a paid theme or did you customize it yourself? Either way keep up the nice quality writing, it?s rare to see a nice blog like this one nowadays..

This website online is mostly a stroll-by means of for all the data you wished about this and didn?t know who to ask. Glimpse right here, and also you?ll definitely uncover it.

Thanks for the concepts you have provided here. Moreover, I believe there are a few factors that keep your automobile insurance premium lower. One is, to take into account buying cars and trucks that are within the good listing of car insurance corporations. Cars which have been expensive tend to be at risk of being robbed. Aside from that insurance is also using the value of your car, so the more expensive it is, then higher the particular premium you spend.

This is the correct weblog for anybody who wants to search out out about this topic. You notice so much its almost hard to argue with you (not that I actually would need?HaHa). You positively put a brand new spin on a topic thats been written about for years. Nice stuff, simply nice!