Inspect different types of bearing parts like taper rollers, ball bearings to inspect for surface defects and assembly integrity.

Architecture Diagram

Our inspection system can easily detect roller defects (inner ring / outer ring/rollers).

In the Automotive Industry bearing is a very critical component. Defects such are unfinished surfaces, scratches on machined surfaces, etc can occur due to either improper handling or processes. Our machine vision systems can be trained to look for these defects reliably and accurately. Yet at the same time, we ensure that good parts are not flagged as defective.

Qualitas has developed a solution for identifying these defects using the latest Deep Learning Artificial Intelligence Technologies, making it one of the most accurate systems available in the industry.

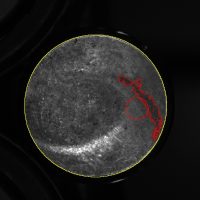

Some Roller Defects

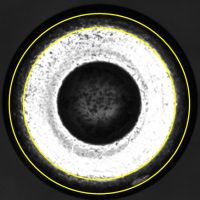

Quality Inspection of Bearing Balls

Surface defects on ball bearings can also affect the stability and service life of the bearing. To inspect it accurately and identify defective steel balls is very necessary for the development of the bearing industry and its application fields. Every machine vision requirements is unique we customize and build application as per the customer requirements.

Our solutions are running successfully across a variety of different industries and applications.

Images Captured by the Vision System